THE INDUSTRY LEADING BREAKDOWN BOOKING SYSTEM

BOOK & TRACK SERVICE JOBS WITH HYDRAQUIP’S JOB MANAGER

24/7 UK nationwide coverage

Book & track service jobs

Before & after job site photos

Real-time job status updates

95% first-time fix rate

Qualified & trained engineers

24 HOUR ON SITE HOSE REPAIR SERVICE

Keeping your running day and night. 24 Hour Number: 0345 812 0212

At Hydraquip, we understand the critical importance of minimising downtime in your operations. Our 24/7 Onsite Hose Repair Service ensures that your site breakdowns are addressed promptly and effectively, keeping your machinery running smoothly.

24/7 HOSE REPAIR

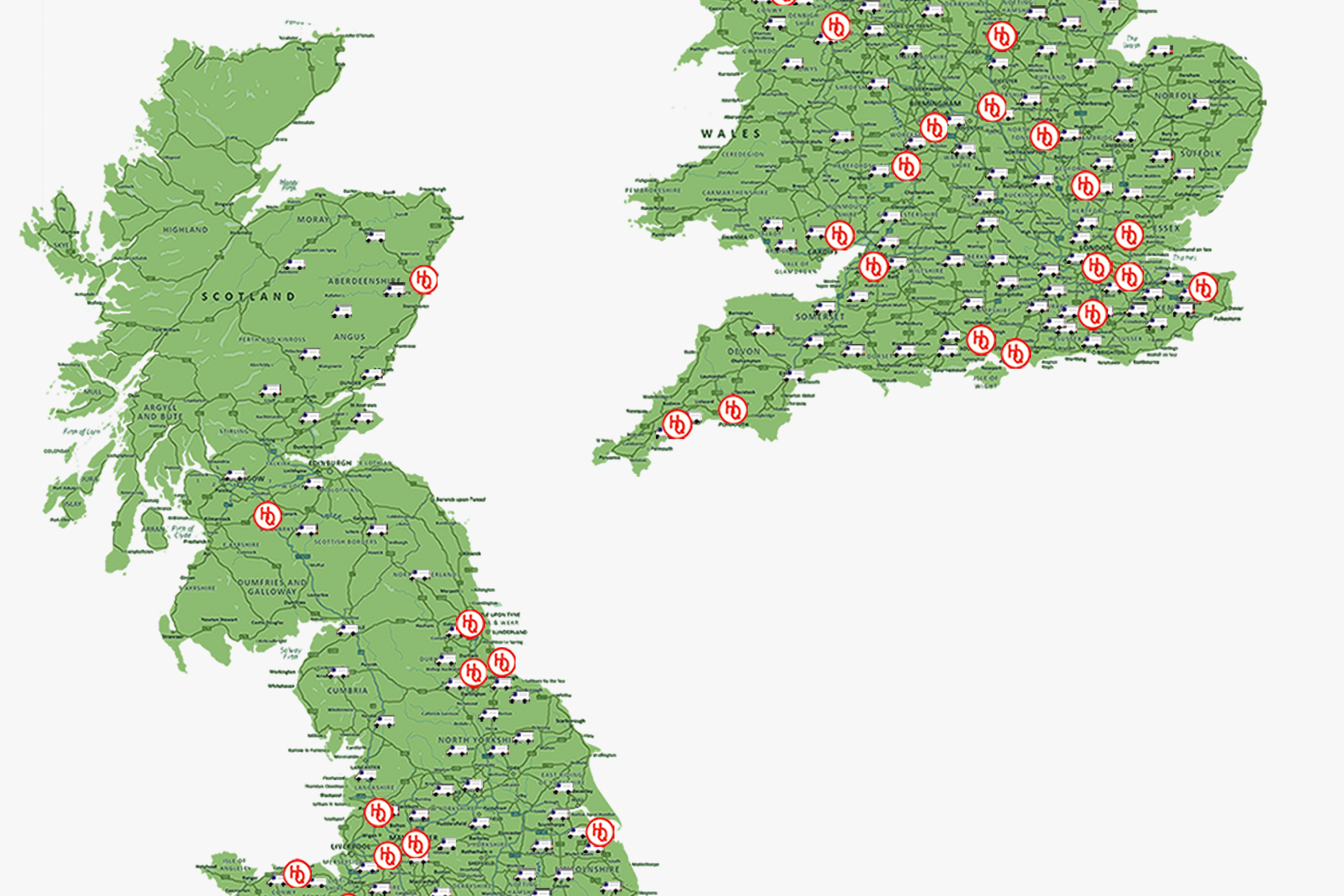

Hydraquip operate a fleet of 148 on site hose mobile replacement workshops across the country working around the clock addressing emergency breakdowns, maintenance needs or scheduled installations. We recognise the pivotal role hoses play in a hydraulic system, our service not only prioritises quick response times but also underscores precision and quality in every aspect.

RAPID RESPONSE

Hydraquip’s fleet on site hose vans are strategically positioned and operated by skilled hydraulic technicians who ensure swift deployment to your locations. With fully equipped mobile workshops, Hydraquip bring the tools and expertise directly to you, minimising downtime and ensuring a rapid solution to your hydraulic breakdown. Trust Hydraquip to keep your machinery running smoothly day and night.

TRADE COUNTERS

Hydraquip’s trade counters offer repair services including hydraulic rams, cylinders, pumps and hydraulic motors. With in-house capabilities for manufacturing hose assemblies to pattern whilst catering to larger OEM requirements with services such as labelling, testing, bagging and assembling parts for multi component kits. Serving various industries: Agriculture, Aviation, Construction, Manufacturing, Marine, Offshore and Plant Hire.

HYDRAQUIP ENGINEERS

Hydraquip’s engineers are fully trained to the latest industry standards. The fleet of engineers are strategically located across the UK to pass the benefits of quick response times. Engineers are trained will make up hose assemblies on site to get your machinery up and running in the fastest time possible. Our satellite tracked workshops carry a comprehensive range of hydraulic hose and fittings to allow our engineers to complete repairs on site there and then.

WHY HYDRAQUIP?

24/ 7 Working Around The Clock

148 Engineers

Experienced Engineers

Nationwide Coverage

Online Service Job Booking & Tracking Portal

28 Trade Counter Branches

UNLOCK THE POWER OF JOB MANAGER ANYWHERE AND ANYTIME

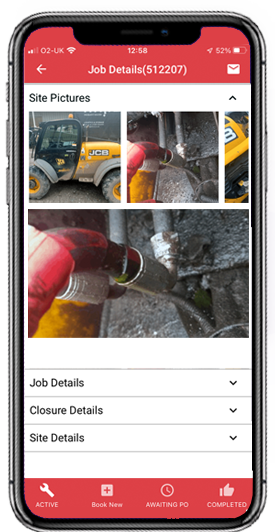

Job Manager App – Imagine being on site, with limited computer access and still having the ability to effortlessly book your service job. That’s the magic of our Job Manager app. It’s your go to tool for seamless job management, providing unmatched convenience and efficiency.

APP BOOKING

Book a repair from your app

AVAILABLE 24/7

Book anytime from anywhere

JOB HISTORY

Electronic Job Sheets

REGISTER HERE

Complete the brief registration form to get started. Signing up is incredibly simple, which takes just a couple of minutes. You’ll be in control of your account in no time.

When setting up your account, our team members will provide a software demo, putting you firmly in the driving seat and prepared to get you started.

Book & Track Jobs - Registration

MANULI HOSE

The Manuli Rockmaster is a medium to high pressure hose range used in heavy duty environmental conditions and specific installations with severe abrasion conditions, such as marine applications, underground and open pit mining. Manuli Rockmaster is standard in all Hydraquip workshops and trade counters.

– Superior abrasion resistance

– High ozone and weather resistance

– Flame resistance to a wide range of spec

– Antistatic and antitoxic cover

– Above standard pressure resistance

FOC HOSE TRACEABILITY

Hydraquip’s offer its customers complete security, traceability and fraud prevention with every hose replaced on a breakdown barcoded with a unique serial number.

Our barcode technology is used to enhance identification and reduce errors. Hydraquip’s searchable database can be securely accessed to reveal electronic details of the hose and the components used, ensuring data is readily available. View the history of our hose on our online service portal, Job Manager.

– Enhanced Identification

– Traceability and Data Accessibility

– Online Service Portal Database

SITE PHOTOS

Before and after job site photos are taken by the engineer of the fault and machine being worked on. These photos are available to view either on the electronic job sheet or by logging into the Job Manager online portal allowing customers to accurately asses the costs involved or address a warranty claim. Job site photos will showcase a selection of images displaying the machine, manufacturers serial plate, defective part, oil level and hose level if available.

– Historic Visual Job Records

– Detailed Image Selection

– Info for Cost Assessment & Warranty Claims